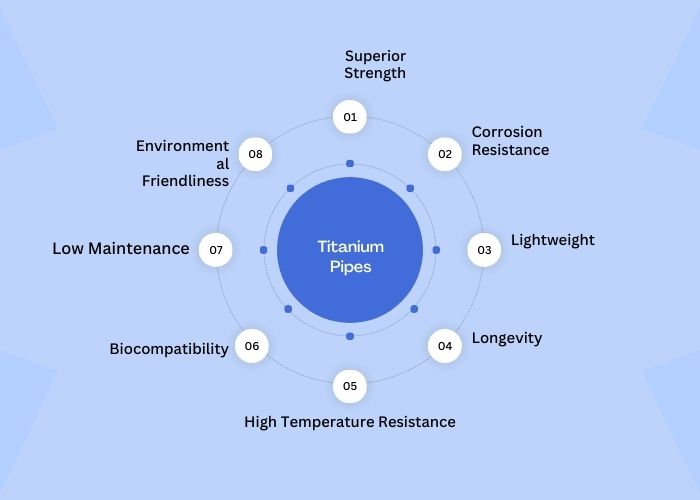

Titanium pipe is highly valued in many industries because of its unique properties. They are known for their incredible strength, corrosion resistance and lightweight nature, making them indispensable for aerospace, chemical applications, medical applications and marine environments. Their durability ensures long-term performance, making them a desirable choice where reliability is high. In addition, their resistance to extreme temperatures and harsh conditions further emphasizes their importance in harsh environments. Specifically, titanium pipe provides a reliable solution for high-strength and corrosion-resistance applications.

| Standards : | ASTM B862, B861 / ASME SB862, SB861 |

| Dimensional : | ANSI/ASME X6.19M, ANSI/ASME X6.10M |

| Seamless Pipe Size : | 1 / 2″ NB – 16″ NB |

| Welded Pipe Size : | 1 / 2″ NB – 24″ NB |

| Outside Diameter : | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Pipe Type : | Seamless / Welded / ERW / Fabricated / CDW / 100% X Ray Welded |

| Thickness Range : | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Pipes End : | Plain End, Beveled End, Treaded One End, TBE (Treaded Both Ends) |

| Value Added Services : | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

| Grade | C | N | O | H | Ti | Fe |

| Titanium | .08 max | .03 max | .18 max | .015 max | Bal | .20 max |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Titanium | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20 % |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Titanium Pipes as per DIN, ISO, JIS or ANSI Standard.

Titanium Pipes applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Yes, titanium pipes can be welded. However, welding titanium requires specialized techniques and equipment due to its high reactivity with oxygen and nitrogen at elevated temperatures. Proper shielding gas and inert atmosphere are essential to prevent contamination and achieve high-quality welds. Additionally, thorough cleaning and preparation of the welding area are crucial to ensure successful welds and maintain the integrity of the titanium material. Overall, while welding titanium is possible, it requires expertise and careful handling to achieve reliable and durable weld joints.

Yes, titanium pipes typically do not require corrosion protection coatings due to their inherent resistance to corrosion in many environments. Titanium forms a stable oxide layer that protects against most corrosive agents, making coatings unnecessary in most applications. However, specific conditions such as extreme temperatures or highly aggressive chemicals may warrant additional protective measures.

When installing titanium pipes, consider corrosion resistance, compatibility with other materials, and specialized welding techniques due to titanium’s properties.

Yes, titanium pipes can be recycled after use. They are valuable in recycling due to their high durability and corrosion resistance. Recycling titanium helps conserve resources and reduces environmental impact.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.