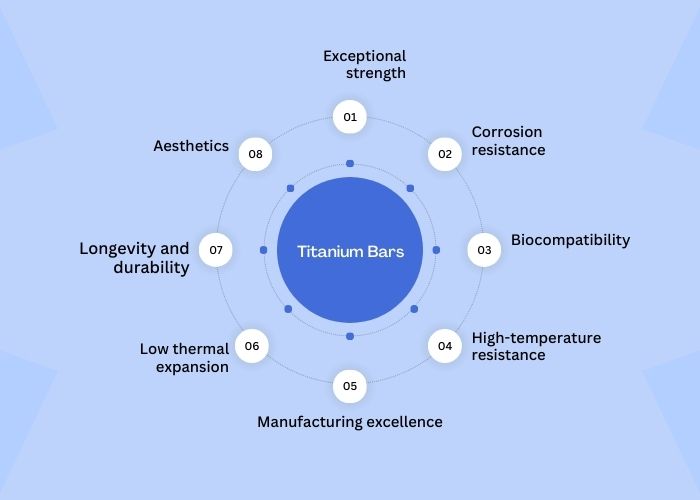

We are pleased to offer a wide range of Titanium Bars sourced from reputable vendors known for crafting high-quality titanium products. These bars are essential in many applications and are available in different sizes and grades to meet industry standards and customer requirements. Widely used in construction and engineering, our Titanium Bars are highly resistant to corrosion and abrasion, ensuring durability in tough conditions. Using titanium alloys strengthens these bars during heat treatment, improving their mechanical properties consistently across their entire structure.

| Specifications | : | ASTM B348/ ASTM SB348 |

| Dimensions | : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Size | : | 5 mm To 500 mm |

| Diameter | : | 0.1 mm to 100 mm |

| Length | : | 100 mm To 3000 mm Long & Above |

| Finish | : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Tolerance | : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Form | : | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Grade | Tensile Strength | Yield Strength | Elongation In 2 In. Or 50mm Min.,% | Bend Test | |||||

|---|---|---|---|---|---|---|---|---|---|

| Min | Min | Min | Min | Max | Max | Under 0.070 In. (1.8mm) Thickness | 0.070 To 0.187 In. (1.8mm To 4.75mm) Thickness | ||

| Ksi | Mpa | Ksi | Mpa | Ksi | Mpa | ||||

| 1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 | 1.5T | 2T |

| 2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 | 2T | 2.5T |

| 3 | 65 | 450 | 55 | 380 | 80 | 550 | 18 | 2T | 2.5T |

| 4 | 80 | 550 | 70 | 483 | 95 | 655 | 15 | 2.5T | 3T |

| 5 | 130 | 895 | 120 | 828 | … | … | 10 | 4.5T | 5T |

| 7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 | 2T | 2.5T |

| 9 | 90 | 620 | 70 | 483 | … | … | 15 | 2.5T | 3T |

| 12 | 70 | 483 | 50 | 345 | … | … | 18 | 2T | 2.5T |

| Grade | C | N | O | H | Ti | Fe |

| Gr 1 | .08 Max | .03 Max | .18 Max | .015 Max | Bal | .20 Max |

| Gr 4 | .08 Max | .05 Max | .40 Max | .015 Max | Bal | .50 Max |

| Gr 7 | .08 Max | .03 Max | .25 Max | .015 Max | Bal | .30 Max |

| Gr 9 | .08 Max | .03 Max | .15 Max | .015 Max | – | .25 Max |

| Gr 12 | .08 Max | .03 Max | .25 Max | 0.15 Max | – | .30 Max |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Titanium Bars as per DIN, ISO, JIS or ANSI Standard.

Titanium Bars applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Yes, Titanium bars can be recycled after use. Titanium is highly recyclable due to its durability and resistance to corrosion, making it valuable for reuse in various industries such as aerospace, automotive, and medical. Recycling titanium helps conserve natural resources and reduce energy consumption compared to primary production methods.

Titanium Bars are highly suitable for cryogenic applications due to their exceptional strength-to-weight ratio, corrosion resistance, and low thermal expansion characteristics. These properties make titanium bars ideal for maintaining structural integrity and performance at extremely low temperatures, commonly found in cryogenic environments such as aerospace, medical, and scientific research applications.

Titanium bars can be used for underground applications due to their excellent corrosion resistance. They withstand exposure to moisture, soil acidity, and other underground conditions that can degrade other materials. Their high strength and durability make them ideal for structural support in tunnels, pipelines, and other underground infrastructure projects.

When selecting Titanium Bars for your application, consider the following factors: desired strength-to-weight ratio, corrosion resistance requirements, operating temperature range, and compatibility with other materials if necessary. Choose a grade of Titanium (Grade 5 for high strength or Grade 2 for general corrosion resistance) that best matches these criteria to ensure optimal performance and longevity in your specific use case.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.