Home > Super Duplex > Super Duplex Steel Flanges

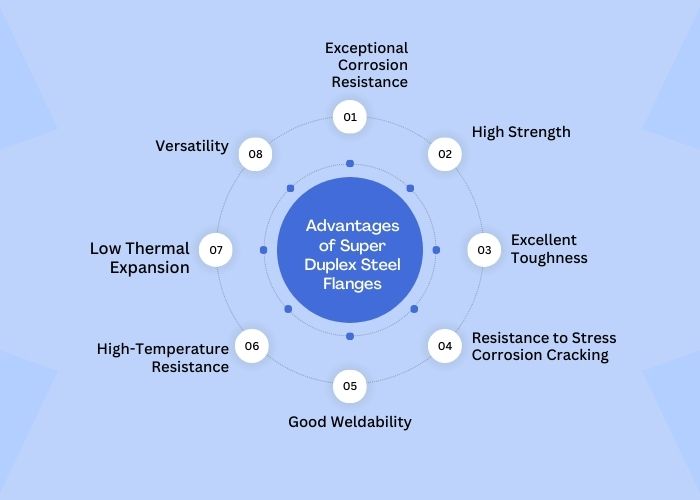

Super duplex steel flanges are integral fittings in piping systems chosen for their outstanding corrosion resistance and mechanical properties. This type of steel is highly alloyed, with elevated levels of chromium, molybdenum, and nitrogen compared to standard duplex steel grades.

| Specifications | ASTM A182 / ASME SA182 |

| Size | 1/8″ NB TO 24″ NB |

| Standards | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Grades | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Material | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| Super Duplex Steel Flanges |

0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

| Material Product | Tensile Strength ksi | Proof Strength 0.2% ksi (minimum) | Elongation (%) (minimum) | Hardness Rockwell C |

|---|---|---|---|---|

| Super Duplex Steel Flanges | 860 | 720 minimum | 16 minimum | 270 maximum |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Super Duplex Steel Flanges as per DIN, ISO, JIS or ANSI Standard.

Super duplex steel flanges are widely utilized across numerous industries for their exceptional corrosion resistance and mechanical properties. Commonly found in demanding environments such as oil and gas, chemical processing, marine, offshore, and desalination plants, these flanges play a pivotal role in ensuring the integrity and reliability of piping systems.

Yes, Super Duplex Steel Flanges can be recycled after use. Steel is highly recyclable, and Super Duplex Steel maintains its properties even through recycling processes, making it a sustainable choice for environmental conservation and resource efficiency.

Yes, Super Duplex Steel Flanges are suitable for underground applications due to their excellent corrosion resistance, which includes resistance to chloride stress corrosion cracking and other harsh environments often encountered underground. Their high strength and durability are ideal for ensuring long-term reliability in underground piping systems.

To select the right Super Duplex Steel Flanges, consider factors like the operating conditions (temperature, pressure), corrosion resistance requirements (including exposure to harsh environments), compatibility with other components, flange dimensions and ratings (ANSI/ASME standards), and specific application needs (such as offshore drilling, chemical processing, or marine environments). Consulting with suppliers for technical guidance based on your project’s specifications can ensure you choose flanges that meet performance and durability expectations.

When installing Super Duplex Steel Flanges, ensure proper alignment and tightening to prevent leaks. Consider the compatibility with other materials in the piping system and adhere to recommended torque values for bolts to maintain integrity under high-pressure conditions.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.