Home > Stainless Steel > Stainless Steel Pipe Fittings

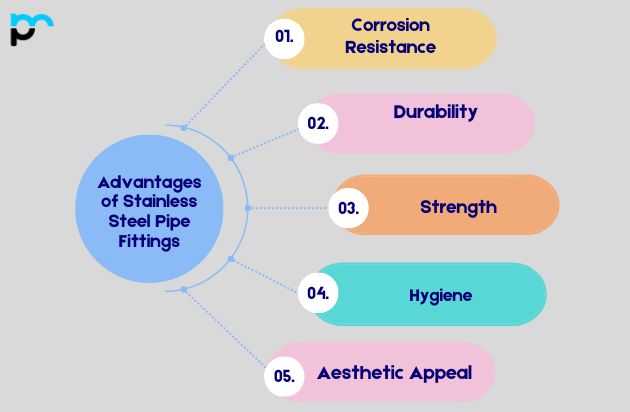

Embark on a journey of unparalleled quality with our stylish stainless steel pipe fittings featured on our curated product pages. Immerse yourself in an unparalleled versatility and reliability world, where every fitting is optimized for various technical applications. Our commitment to quality shines through in every product, which is perfectly designed to the highest durability and corrosion resistance standards. As your trusted supplier, we prioritize customer satisfaction by offering customized processes, competitive pricing and fast delivery, ensuring a seamless experience for your manufacturers, construction, or engineering work. Experience improved project results with our strong commitment to delivering reliable solutions that redefine industry standards.

| Grades | 201, 202, 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L |

| Type | Seamless / Welded / Fabricated |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Size | ½”NB to 48″NB in |

| Schedule | Sch 10s, 40s, 80s, 160s, XXS. |

| Dimensions | ANSI/ASME B16.9, B16.28, MSS-SP-43. |

| Density | 8.0 g/cm3 |

| Melting Point | 1400 °C (2550 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

| SS | 304 | 304N | 304LN |

|---|---|---|---|

| Ni | 8 – 11 | 8 – 11 | 8 – 11 |

| Fe | Balance | ||

| Cr | 18 – 20 | 18 – 20 | 18 – 20 |

| C | 0.08 max | 0.08 max | 0.035 max |

| Si | 0.75 max | 0.75 max | 0.75 max |

| Mn | 2 max | 2 max | 2 max |

| P | 0.040 max | 0.040 max | 0.040 max |

| S | 0.030 max | 0.030 max | 0.030 max |

| N | 0.10 – 0.16 | 0.10 – 0.16 | |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Stainless Steel Pipe Fittings as per DIN, ISO, JIS or ANSI Standard.

Stainless Steel Pipe Fittings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Yes, stainless steel pipe fittings are highly suitable for hygienic and sanitary applications due to their non-porous nature, corrosion resistance, and ease of cleaning. These fittings are commonly used in industries such as food processing, pharmaceuticals, and healthcare, where maintaining cleanliness and preventing bacterial contamination are critical requirements. The inert properties of stainless steel make it an ideal choice for ensuring product purity and meeting strict hygiene standards in sensitive environments.

Stainless steel pipe fittings are generally resistant to galvanic corrosion due to their inherent properties. Chromium in stainless steel forms a protective oxide layer that helps prevent galvanic reactions with other metals. However, in certain circumstances where there is direct contact with dissimilar metals and electrolytes, such as in marine environments or industrial settings, galvanic corrosion may occur. Proper insulation and material selection can help mitigate the risk of galvanic corrosion in stainless steel pipe fittings.

Yes, stainless steel pipe fittings are highly recyclable and are considered valuable materials in the recycling industry. After their service life, stainless steel fittings can be collected, processed, and recycled into new products without losing their quality or properties. Recycling stainless steel is a sustainable practice that helps conserve resources, reduce waste, and minimize environmental impact, making it an eco-friendly choice for a circular economy.

Stainless steel pipe fittings are well-suited for cryogenic applications due to their excellent low-temperature properties. With the right stainless steel grade selection, these fittings can maintain high strength, toughness, and corrosion resistance at extremely low temperatures. Their reliability in cryogenic environments makes them a preferred choice in aerospace, medical, and energy industries, where materials must withstand sub-zero conditions without compromising performance.

Call Us: +91 7208967217

Email: sales@www.pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.