Home > Stainless Steel > Stainless Steel Pipe

Discover our top-quality stainless steel pipes on our product pages, offering a wide range of solutions for various industrial applications. Our SS pipes are designed to meet industry durability and corrosion resistance standards. As a trusted supplier, we focus on customer satisfaction, providing customizable options, competitive prices, and efficient delivery. Our SS pipes are ideal for construction, infrastructure, and industrial projects, meeting the highest quality benchmarks. Enhance your projects with our reliable and innovative solutions, supported by a commitment to quality and performance.

| Specifications | ASTM A312/A358, ASME SA312/SA358 |

| Dimensions | ASTM, ASME and API |

| Standard | JIS, AISI, ASTM, GB, DIN, EN, etc. |

| Surface | Brushed, Mill Finished, Anodized, Sand Blasted, Finished Polished. |

| Seamless Pipes Size | 1/2″ NB – 24″ NB. |

| ERW Pipes Size | 1/2″ NB – 24″ NB. |

| EFW Pipes Size | 6″ NB – 100″ NB. |

| Form | Round, Square, Rectangular, Hydraulic etc. |

| Length | Single Random, Double Random & Cut Length. |

| Types | Seamless / ERW / Welded / Fabricated / LSAW Pipes. |

| ELEMENT | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| Stainless Steel Pipe | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 | – |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Stainless Steel Pipe as per DIN, ISO, JIS or ANSI Standard.

The main difference between stainless steel pipes and tubes is their dimensions and applications. Pipes are typically measured by their internal diameter (ID) and are designed for transporting fluids and gases. Conversely, tubes are measured by their outside diameter (OD) and are used for structural applications or applications requiring a precise outside diameter, such as in instrumentation or mechanical components. Tubes are generally more rigid than pipes due to their thicker walls and are often used in industries where strength and durability are crucial.

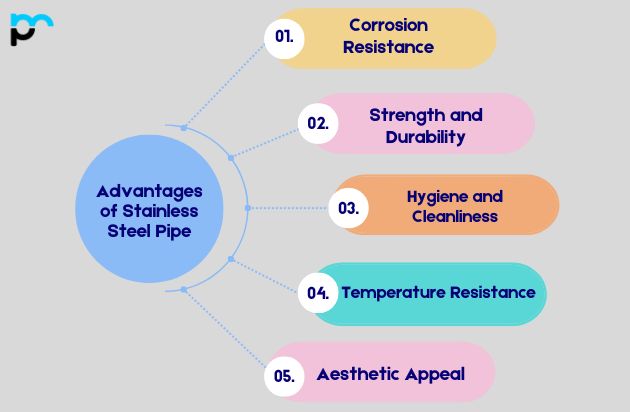

Corrosion Resistance : Stainless steel pipes are highly resistant to corrosion from exposure to water, moisture, and various chemicals. This resistance ensures longevity and reliability, even in harsh environments.

Strength and Durability: Stainless steel pipes are known for their superior strength and durability. They can withstand high pressures, mechanical stress, and impact without cracking or deforming, making them ideal for demanding applications.

Hygiene and Cleanliness: Due to their smooth, non-porous surface, stainless steel pipes are easy to clean and do not harbour bacteria or other pathogens. This makes them suitable for use in food processing, pharmaceutical, and healthcare industries where hygiene is paramount.

Temperature Resistance : Stainless steel pipes maintain their structural integrity and mechanical properties at high and low temperatures. They perform well in extreme heat and cold, making them versatile for various industrial applications.

Aesthetic Appeal : Stainless steel pipes have a sleek, modern appearance that is visually appealing. Their shiny, polished finish enhances the look of industrial and architectural projects, contributing to their popularity in visible installations.

Stainless Steel Pipe applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

When selecting stainless steel pipe for industrial use, key criteria include corrosion resistance, which ensures longevity and reliability in various environments; strength and durability to withstand pressure and mechanical stress; and compatibility with the application’s specific requirements, such as temperature extremes or exposure to chemicals. Additionally, considerations like size, wall thickness, and cost-effectiveness play important roles in the selection process.

Seamless pipes are manufactured without any welding seam, typically by extruding the raw material into a hollow tube. This process results in a uniform, round cross-section with no joints, making seamless pipes stronger and more reliable for high-pressure applications. Welded pipes, conversely, are made by rolling a flat plate into a tube and then welding the seam. While cheaper to manufacture, welded pipes may have weaker seams susceptible to corrosion and are generally used for lower-pressure applications or where a seamless option is unnecessary.

Yes, stainless steel pipes are highly recyclable. They can be melted down and reused multiple times without losing their inherent properties, making them a sustainable choice for various applications.

Choose a stainless steel pipe based on factors like corrosion resistance (grade 304 for general use, 316 for marine environments), temperature and pressure requirements, and compatibility with the fluid being transported (chemical resistance). Consulting with a supplier or engineer can help ensure the right choice for your specific application.

When installing stainless steel pipes underground, ensure they are properly coated or wrapped to prevent corrosion. Suitable bedding materials should protect the pipes from physical damage and provide adequate support. Regular inspections for signs of corrosion and proper drainage are also essential for long-term durability.

| Pipe Size | O.D. inches | Pipe Schedule | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 5 | 10 | 40 | STD | 80 | XH | 160 | XXH | ||

| 1/8 | 0.405 | .1383 | .1863 | .2447 | .2447 | .3145 | .3145 | ||

| 1/4 | 0.540 | .2570 | .3297 | .4248 | .4248 | .5351 | .5351 | ||

| 3/8 | 0.675 | .3276 | .4235 | .5676 | .5676 | .7388 | .7388 | ||

| 1/2 | 0.840 | .5380 | .6710 | .8510 | .8510 | 1.088 | 1.088 | 1.304 | 1.714 |

| 3/4 | 1.050 | .6838 | .8572 | 1.131 | 1.131 | 1.474 | 1.474 | 1.937 | 2.441 |

| 1 | 1.315 | .8678 | 1.404 | 1.679 | 1.679 | 2.172 | 2.172 | 2.844 | 5.214 |

| 1-1/4 | 1.660 | 1.107 | 1.806 | 2.273 | 2.273 | 2.997 | 2.997 | 3.765 | 5.214 |

| 1-1/2 | 1.900 | 1.604 | 2.085 | 2.718 | 2.718 | 3.631 | 3.631 | 4.859 | 6.408 |

| 2 | 2.375 | 1.604 | 2.638 | 3.653 | 3.653 | 5.022 | 5.022 | 7.444 | 9.029 |

| 2-1/2 | 2.875 | 2.475 | 3.531 | 5.793 | 5.793 | 7.661 | 7.661 | 10.01 | 13.69 |

| 3 | 3.500 | 3.029 | 4.332 | 7.576 | 7.576 | 10.25 | 10.25 | 14.32 | 18.58 |

| 3-1/2 | 4.000 | 3.472 | 4.973 | 9.109 | 9.109 | 14.98 | 12.50 | 22.85 | |

| 4 | 4.500 | 3.915 | 5.613 | 10.79 | 10.79 | 14.98 | 14.98 | 22.51 | 27.54 |

| 5 | 5.563 | 6.349 | 7.770 | 14.62 | 14.62 | 20.78 | 20.78 | 32.96 | 38.55 |

| 6 | 6.625 | 7.585 | 9.289 | 18.97 | 18.97 | 28.57 | 28.57 | 45.30 | 53.16 |

| 8 | 8.625 | 9.014 | 13.40 | 28.55 | 28.55 | 43.39 | 43.39 | 74.69 | 72.42 |

| 10 | 10.750 | 15.19 | 18.70 | 40.48 | 40.48 | 64.33 | 54.74 | ||

| 12 | 12.750 | 20.93 | 24.16 | 53.52 | 49.56 | 88.51 | 65.42 | ||

| 14 | 14.000 | 42.05 | 63.37 | 54.57 | 106.1 | 72.09 | |||

| 16 | 16.000 | 42.05 | 82.77 | 62.58 | 136.5 | 82.77 | |||

| 18 | 18.000 | 47.39 | /104.8 | 70.59 | 170.8 | 93.45 | |||

| 20 | 20.000 | 52.73 | 122.9 | 78.60 | 208.9 | 104.1 | |||

| 24 | 24.000 | 63.41 | 171.2 | 94.62 | 296.4 | 125.50 | |||

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.