Home > Stainless Steel > Stainless Steel Forged Fittings

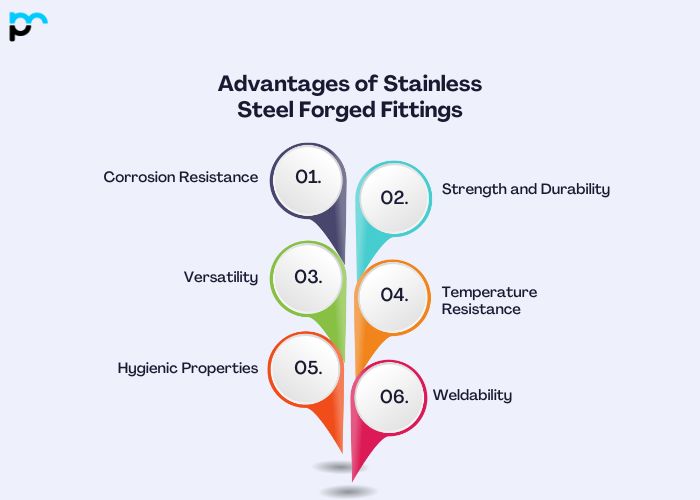

Stainless steel Forged fittings are used to connect pipes in various industrial applications. These fittings are manufactured through the forging process, where pressure is applied to shape and mould stainless steel into a desired fitting configuration. Known for their exceptional strength, durability and corrosion resistance, stainless steel forged fittings are ideal for our environments requiring high-pressure or high-temperature operation. They are important in oil and gas, chemical processing, and Power generation.

| Specifications | ASTM A403/ ASME SA403 |

|---|---|

| Size | Seamless Butt Weld Fittings : 1/2″ – 10″ Welded Butt Weld Fittings : 1/2″ – 48″ |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Specialized manufacturer of | 90º Elbows, 45º Elbows, Tees, Cross, Reducer, Pipe Cap, Stub End, Pipe Bend |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni |

| Stainless Steel Forged Fittings | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Stainless Steel Forged Fittings as per DIN, ISO, JIS or ANSI Standard.

Stainless Steel Forged Fittings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Stainless steel forged fittings typically do not require additional corrosion protection coatings due to the inherent corrosion resistance of stainless steel. However, supplementary coatings like epoxy or galvanization may be considered for added protection in highly corrosive environments or specific applications.

Yes, stainless steel forged fittings are highly recyclable. Stainless steel is a sustainable material known for its recyclability, making it an environmentally friendly choice for fittings as it can be melted down and reused in various applications without losing its properties.

When selecting stainless steel forged fittings, consider operating conditions (temperature, pressure), material grade compatibility, fitting configuration (type, size), compliance with industry standards, application-specific requirements, and the supplier’s reputation for quality assurance.

Yes, stainless steel forged fittings are suitable for high-temperature applications due to their ability to withstand elevated temperatures without compromising integrity. The forging process enhances their strength and thermal resistance, making them reliable in demanding temperatures.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.