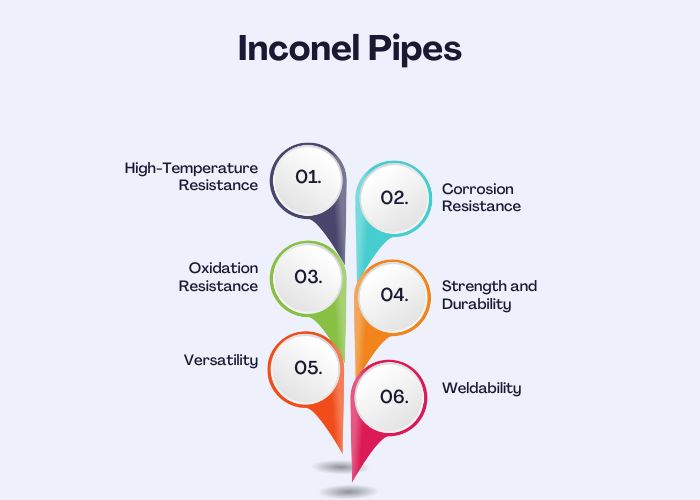

Inconel pipes are highly regarded nickel-chromium alloys known for their excellent resistance to extreme temperatures, corrosion, and oxidation. They are widely used in challenging industries like chemicals, aerospace, marine engineering, and nuclear sectors due to their durability and ability to withstand tough conditions. Inconel pipes are favoured for critical applications requiring reliable performance and longevity.

|

Dimensions |

: |

ASTM, ASME and API |

|

Standard |

: |

ASTM B163/ ASME SB163 |

|

Size |

: |

1/8″NB TO 30″NB IN |

|

Specialized in |

: |

Large Diameter Size |

|

Schedule |

: |

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

|

Form |

: |

Round, Hydraulic Etc |

|

Type |

: |

Seamless / ERW / Welded / Fabricated / LSAW Pipes |

|

Length |

: |

Single Random, Double Random & Cut Length. |

|

End |

: |

Plain End, Beveled End, Threaded |

|

Cu |

Ni |

Fe |

Mn |

C |

S |

Si |

Cr |

|

0.5 max |

72.0 min |

6.0 – 10.0 |

1.0 max |

0.15 max |

0.015 max |

0.5 max |

14.0 – 17.0 |

|

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

8.47 g/cm3 |

1413 °C (2580 °F) |

Psi – 95,000 , MPa – 655 |

Psi – 45,000 , MPa – 310 |

40 % |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Inconel Pipes as per DIN, ISO, JIS or ANSI Standard.

Inconel Pipe applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Recycling Inconel pipes offers significant environmental benefits by reducing the demand for virgin materials and energy-intensive mining processes. It conserves natural resources such as nickel and chromium, essential components of Inconel alloys. Recycling also minimizes landfill waste and reduces greenhouse gas emissions associated with manufacturing new materials. Overall, it contributes to a more sustainable and environmentally friendly industrial cycle.

|

Inconel pipe OD (millimeter) |

Sch |

kilogram-meter |

inches |

Pipe WT(millimeter) |

|

26.67 |

80S |

2.23 |

3/4 |

3.91 |

|

33.40 |

10S |

2.13 |

1 |

2.77 |

|

114.30 |

40S |

16.32 |

4 |

6.02 |

|

33.40 |

160 |

4.30 |

1 |

6.352 |

|

42.16 |

10S |

2.73 |

1¼ |

2.77 |

|

42.16 |

40S |

3.44 |

1¼ |

3.56 |

|

114.30 |

10S |

8.50 |

4 |

3.05 |

|

42.16 |

80S |

4.53 |

1¼ |

4.85 |

|

42.16 |

160 |

5.69 |

1¼ |

6.352 |

|

48.26 |

80S |

5.49 |

1½ |

5.08 |

|

60.33 |

10S |

3.99 |

2 |

2.77 |

|

48.26 |

40S |

4.11 |

1½ |

3.68 |

|

60.33 |

80S |

7.60 |

2 |

5.54 |

|

21.34 |

10S |

1.02 |

1/2 |

2.11 |

|

60.33 |

160 |

11.29 |

2 |

8.742 |

|

73.03 |

80S |

11.59 |

2½ |

7.01 |

|

88.90 |

10S |

6.56 |

3 |

3.05 |

|

13.72 |

80S |

0.81 |

1/4 |

3.02 |

|

17.15 |

40S |

0.86 |

3/8 |

2.31 |

|

88.90 |

40S |

11.47 |

3 |

5.49 |

|

219.08 |

40S |

43.20 |

8 |

8.18 |

|

88.90 |

80S |

15.51 |

3 |

7.62 |

|

60.33 |

40S |

5.52 |

2 |

3.91 |

|

48.26 |

10S |

3.16 |

1½ |

2.77 |

|

88.90 |

160 |

21.67 |

3 |

11.132 |

|

101.60 |

10S |

7.53 |

3½ |

3.05 |

|

168.28 |

120 |

54.75 |

6 |

14.27 |

|

114.30 |

80S |

22.67 |

4 |

8.56 |

|

33.40 |

80S |

3.29 |

1 |

4.55 |

|

168.28 |

160 |

68.59 |

6 |

18.262 |

|

219.08 |

120 |

91.30 |

8 |

18.23 |

|

141.30 |

40S |

22.10 |

5 |

6.55 |

|

17.15 |

10S |

0.64 |

3/8 |

1.65 |

|

101.60 |

40S |

13.78 |

3½ |

5.74 |

|

26.67 |

10S |

1.30 |

3/4 |

2.11 |

|

26.67 |

40S |

1.71 |

3/4 |

2.87 |

|

101.60 |

80S |

18.92 |

3½ |

8.08 |

|

73.03 |

10S |

5.35 |

2½ |

3.05 |

|

73.03 |

40S |

8.77 |

2½ |

5.16 |

|

114.30 |

160 |

34.05 |

4 |

13.492 |

|

13.72 |

10S |

0.50 |

1/4 |

1.65 |

|

13.72 |

40S |

0.64 |

1/4 |

2.24 |

|

168.28 |

10S |

14.04 |

6 |

3.4 |

|

219.08 |

80S |

65.63 |

8 |

12.7 |

|

168.28 |

40S |

28.69 |

6 |

7.11 |

|

17.15 |

80S |

1.12 |

3/8 |

3.20 |

|

21.34 |

40S |

1.29 |

1/2 |

2.77 |

|

141.30 |

160 |

49.87 |

5 |

15.882 |

|

21.34 |

80S |

1.65 |

1/2 |

3.73 |

|

168.28 |

80S |

43.21 |

6 |

10.97 |

|

33.40 |

40S |

2.54 |

1 |

3.38 |

|

141.30 |

80S |

31.44 |

5 |

9.53 |

|

219.08 |

160 |

112.97 |

8 |

23.012 |

Welding can affect the strength of Inconel pipes due to changes in microstructure and the potential introduction of defects like porosity or cracks. Proper welding procedures, including preheating and post-weld heat treatment, minimize these effects and maintain the desired mechanical properties, such as strength and corrosion resistance in Inconel pipes.

Corrosion of Inconel pipes can occur due to exposure to high temperatures, aggressive environments (such as acids or salts), and mechanical stresses. Additionally, improper welding techniques and a lack of protective coatings can accelerate corrosion processes in these pipes. Regular maintenance and appropriate material selection are crucial for minimizing corrosion in Inconel piping systems.

Select the right Inconel pipe by considering temperature, corrosion resistance, and mechanical properties (strength, ductility). Consult suppliers or engineers to match your application’s needs with the appropriate grade (e.g., Inconel 600, 625, 718) and form (seamless or welded). Conduct thorough testing and validation to ensure compatibility with operational conditions.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.