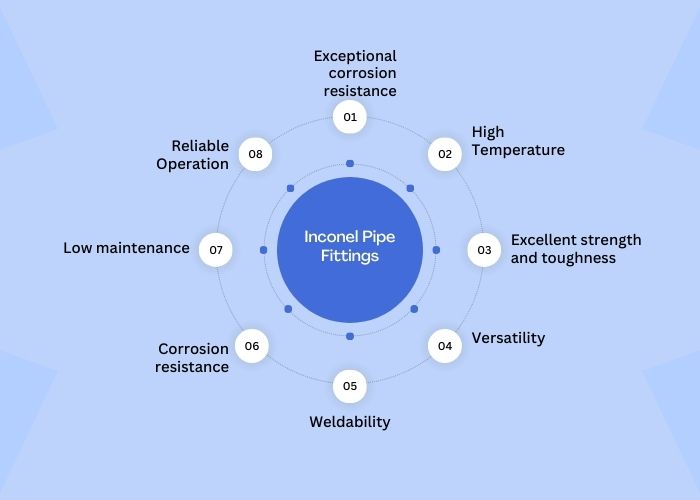

Elevate your industrial performance with our premium selection of Inconel Pipe Fittings, optimized for superior performance in various industrial environments. Our carefully designed materials provide exceptional durability and corrosion resistance, ensuring durability and reliability in harsh environments. Partner with us for flexible solutions, competitive pricing and fast delivery, driving your business to unparalleled levels of quality and innovation.

| Specification | ASTM B366, ASTM SB 366, ASTM B564, ASME SB564 |

| Grade | Inconel 600 (UNS N06600, Alloy 600, 2.4816), Inconel 601 (UNS N06601, Alloy 601, 2.4851), Inconel 625 (UNS N06625, Alloy 625, 2.4856), Inconel 800 (UNS N08800, Alloy 800) |

| Type | Seamless / Welded / Fabricated |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Range | 1/2”NB to 24″NB in Sch 10s, 40s, 80s, 160s, XXS. |

| Dimensions | ANSI/ASME B16.9, B16.28, MSS-SP-43. |

| CONDITION | TENSILE STRENGTH | YEILD STRENGTH | ELOGNATION |

|---|---|---|---|

| ANNEALED, UPTO 4″ (102 MM) | 120 (827) | 60 (414) | 30 |

| ANNEALED, OVER 4″ (102 MM) – 10″(254 MM) | 110 (758) | 50 (345) | 25 |

| Inconel Grade | C | Mg | S | P | Cr | Si | Mo | Ni | Co | Cu | Al | Ti | Ni | I | B |

| Inconel 600 | 0.15 | 1.00 | 0.015 | – | 14.0–17.0 | 0.50 | – | – | – | 0.50 | – | – | 72.0max | 6.0–10.0 | – |

| Inconel 617 | 0.15 | 0.50 | 0.015 | 0.015 | 20.0–24.0 | 0.50 | 8.0–10.0 | – | 10.0–15.0 | 0.50 | 0.8–1.50 | 0.60 | 44.2–56.0 | 3.00max | 0.006 |

| Inconel 625 | 0.10 | 0.50 | 0.015 | 0.015 | 20.0–23.0 | 0.50 | 8.0–10.0 | 3.15–4.15 | 1.00 | – | 0.40 | 0.40 | 58.0max | 5.00max | – |

| Inconel 690 | 0.019 | 0.35 | 0.003 | – | 30.0max | 0.35 | – | – | – | 0.01 | 0.02 | – | 59.5max | 9.20max | – |

| Inconel 718 | 0.08 | 0.35 | 0.015 | 0.015 | 17.0–21.0 | 0.35 | 2.8–3.3 | 4.75–5.5 | 1.00 | 0.2–0.8 | 0.65–1.15 | 0.30 | 50.0–55.0 | balance | 0.006 |

| Inconel X-750 | 0.08 | 1.00 | 0.01 | – | 14.0–17.0 | 0.50 | – | 0.7–1.2 | 1.00 | 0.50 | 0.4–1.0 | 2.25–2.75 | 70.0max | 5.0–9.0 | – |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Inconel Pipe Fittings as per DIN, ISO, JIS or ANSI Standard.

Inconel Pipe Fittings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Recycling Inconel pipe fittings provides environmental benefits by reducing the need for disposal, conserving natural resources and reducing energy consumption in manufacturing. Furthermore, recycling helps to reduce the amount of waste sent to landfills, contributing to a more sustainable and environmentally friendly approach encountered in steel applications. Promoting a circular economy through recycling reduces the environmental impact of new inputs, is consistent with green policies and reduces overall carbon emissions.

When installing Inconel pipe fittings, it’s crucial to consider factors such as proper alignment to prevent stress on the fittings, ensuring secure connections with suitable gaskets or seals to prevent leaks, and adhering to recommended torque values during tightening to maintain structural integrity. Additionally, following manufacturer guidelines for handling and installation procedures can help optimize the performance and longevity of the fittings in the piping system.

Inconel pipe fittings are specially designed for hot, humid environments rather than for construction use. Although exhibiting exceptional strength and durability, they are generally not designed to be load-bearing elements in construction. For construction applications, it is desirable to use materials specifically designed and tested for structural integrity hold and support requirements will implement.

Inconel pipe fittings are known for their inherent corrosion resistance, which is an important design aspect. As a result, additional corrosion protection coatings are generally not required. However, in very severe environments or special applications where additional protection is deemed necessary, additional coatings may be assumed to resist specific corrosive agents or conditions where the suitability has been enhanced. Consultation with corrosion engineers can help to determine the need for and select the appropriate coatings based on the job site and performance requirements.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.