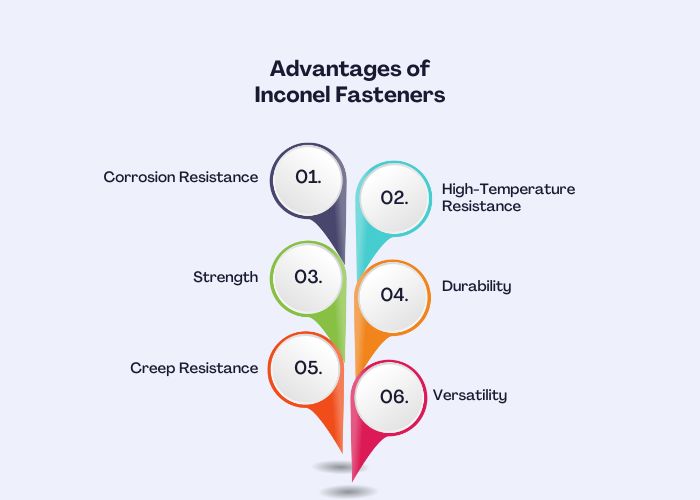

Inconel Fasteners are essential components known for their outstanding performance in extreme conditions. Made from the superalloy Inconel, they offer exceptional resistance to high temperatures, oxidation, and corrosion. This makes them crucial in aerospace, chemical processing, and oil and gas industries, where standard materials often fail. Known for their durability and reliability, Inconel fasteners ensure the integrity and longevity of structures and equipment, protecting critical operations even in the harshest environments.

| Standard of Fasteners | DIN, ASTM, BS and all International Standards |

| Fasteners Length | 3 mm to 200 mm |

| Nuts Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Bolt / Screw Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Machine Screws Size | M1.6 – M12 |

| Washers Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Packing of Fasteners | Wooden pallet, Small Boxs / Carton / Pallet, or as customer request |

| Finish on Fasteners | HDG, Zinc Plated, Zinc Flake, Black Oxide, Xylan or as customer request |

| Grades | |

| Stainless Steel | ASTM / ASME SA 312 GR. 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316TI , 316H , 316 LN , 317 , 317L , 321 , 321H , 347 , 347 H . |

| Duplex Steel | UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 |

Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015 max | 0.30 max | – | 50.00 – 55.00 | 17.00 – 21.00 |

Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Inconel Fasteners as per DIN, ISO, JIS or ANSI Standard.

Inconel fasteners find widespread industrial applications due to their exceptional properties. Their high resistance to corrosion, even in aggressive environments, makes them invaluable in industries such as chemical processing, offshore drilling, and marine engineering, where exposure to corrosive substances is common. Their ability to maintain mechanical integrity at elevated temperatures makes them indispensable in the aerospace, automotive, and power generation sectors.

Inconel fasteners are available in various configurations, including bolts, nuts, screws, washers, studs, and threaded rods. These configurations serve a wide range of applications requiring high-temperature resistance, corrosion resistance, and strength, making Inconel fasteners suitable for aerospace, marine, chemical processing, and high-performance engineering environments.

Yes, Inconel fasteners are highly suitable for high-temperature applications due to their exceptional resistance to heat, oxidation, and thermal fatigue. They maintain their mechanical properties at elevated temperatures, making them ideal for environments where other materials might degrade or fail.

When selecting Inconel fasteners, consider their superior corrosion and oxidation resistance, high strength at elevated temperatures, excellent fatigue resistance, and compatibility with extreme environments. These properties make them ideal for applications requiring reliability under stress, such as aerospace, marine, and chemical processing industries.

Yes, Inconel fasteners are recyclable. They can be reclaimed and reused through processes such as melting and reprocessing, making them environmentally sustainable options for industries requiring high-performance fastening solutions.

Inconel 600 Fasteners Type | SIZE | GRADE | ASME | ISO | ASTM |

|---|---|---|---|---|---|

Inconel 600 Socket Head Cap Fasteners | M1.6 to M64 | 12.9 | B18.3.1 M | 4762 | A574M |

Inconel 600 Socket Low Head Cap Fasteners | M4 to M20 | 10.9 | |||

Inconel 600 Socket Head Shoulder Fasteners | M6 to M24 | 012.9 | B18.3.3M | ||

Inconel 600 Countersunk Socket Head Fasteners | M3 to M20 | 012.9 | B18.3.5M | 10642 | F835M |

Inconel 600 Button Head Socket Fasteners | M3 to M12 | 012.9 | B18.3.4M | 7380 | F835M |

Inconel 600 Flange Button Head Socket Fasteners | M3 to M10 | 012.9 | F835M | ||

Inconel 600 Knurled Point Socket Set Fasteners | M3 to M20 | 45H | B18.3.6M | 4029 | F912M |

Inconel 600 Flat Point Socket Set Fasteners | M6 to M12 | 45H | B18.3.6M | 4026 | F912M |

Inconel 600 Dog Point Socket Set Fasteners | M3 to M20 | 45H | B18.3.6M | 4028 | F912M |

Inconel 600 Cone Point Socket Set Fasteners | M3 to M12 | 45H | B18.3.6M | 4027 | F912M |

Inconel 600 Plain Point Socket Set Fasteners | M3 to M20 | 45H | B18.3.6M | 4029 | F912M |

Inconel 600 Taper Pressure Plug | M8 to M22 | – |

Call Us: +91 7208967217

Email: sales@www.pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.