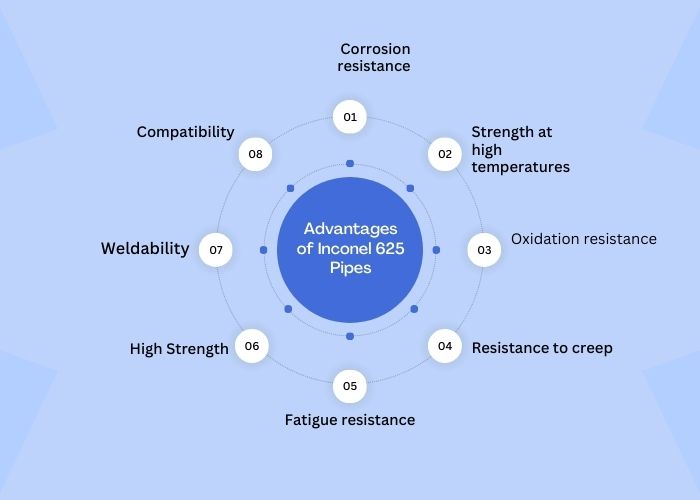

Inconel 625 Pipes are nickel alloy pipes that offer excellent strength and resistance to various corrosive atmospheres. These pipes are widely applied in chemical processing, marine engineering, and aerospace due to their excellent performance at high and low temperatures. Inconel 625 Pipes have excellent fatigue properties and oxidation resistance, making them suitable for high-stress applications.

| Standard | ASTM B444, B705 / ASME SB 444, SB 705 |

| Standard | ASTM, ASME and API |

| Size | 15 NB UP TO 600 NB IN SCH 5S, 10S,10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160 & XXS |

| Length | Single Random, Double Random & Required Length, Cut Length |

| End | Plain End, Beveled End, Treaded |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | – | 5.0 max | 58.0 min | 20.0 – 23.0 |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Inconel 625 pipes as per DIN, ISO, JIS or ANSI Standard.

Inconel 625 pipes applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Several types of Inconel 625 pipe configurations are available, including seamless, welded, ERW, and custom-fabricated pipes to suit various industrial applications.

Yes, Inconel 625 pipes are highly suitable for high-temperature applications due to their exceptional resistance to elevated temperatures, making them ideal for use in aerospace, chemical processing, and power generation industries.

When selecting Inconel 625 pipes, key considerations include corrosion resistance, temperature and pressure ratings, dimensions for fit, compliance with standards, and the supplier’s reputation for quality assurance.

Inconel 625 pipes are not typically recommended for potable water applications due to the potential for leaching of metals into the water, which may not meet regulatory standards for drinking water safety. Stainless steel or other corrosion-resistant materials are more suitable for such applications.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.