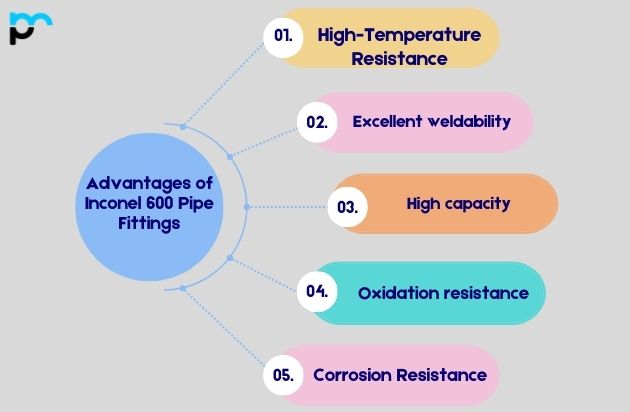

Inconel 600 Pipe Fittings are components used to connect, control, or adapt the flow of Inconel 600 pipes in various industrial systems. Made from the nickel-chromium alloy Inconel 600, these fittings exhibit excellent resistance to high temperatures, corrosion, and oxidation, making them suitable for demanding environments such as chemical processing, heat treating, and nuclear engineering. Common Inconel 600 pipe fittings include elbows, tees, reducers, couplings, and flanges, offering versatility and reliability in critical piping applications.

| Standard | ASTM B366 / ASME SB366 |

| Dimensions | ANSI B16.9, B16.25, B16.28, MSS-SP-43, MSS-SP-48, MSS-SP-59 |

| Size | 1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated) |

| Type | Seamless / Welded(100% X-Ray Welded) / Fabricated |

| Thickness | Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1 max | 0.50 max | 0.015 max | 0.50 max | 6 – 10 | 72.00 min | 14 – 17 |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Inconel 600 Pipe Fittings as per DIN, ISO, JIS or ANSI Standard.

Inconel 600 Pipe Fittings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Inconel 600 pipe fittings typically do not require additional corrosion protection coatings due to their inherent corrosion resistance properties derived from the nickel-chromium alloy composition.

Yes, Inconel 600 pipe fittings are recyclable. The nickel-chromium alloy used in their composition can be recycled and reused in various industries, making them an environmentally sustainable choice.

When selecting Inconel 600 pipe fittings, key considerations include evaluating operating conditions such as temperature and corrosion resistance requirements, ensuring compatibility with existing systems, and adhering to quality standards for optimal performance and longevity.

Yes, Inconel 600 pipe fittings are highly suitable for high-temperature applications due to their exceptional resistance to oxidation and ability to maintain mechanical properties at elevated temperatures, making them a reliable choice for demanding industrial processes.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.