Incoloy pipes are highly regarded nickel-based alloys known for their excellent resistance to corrosion, high temperatures, and oxidation. They are widely used in chemical processing, petroleum refining, power generation, and marine engineering due to their strength, durability, and ability to withstand harsh conditions. Incoloy pipes are the preferred choice for critical applications requiring reliability and high performance, demonstrating advanced engineering and ensuring consistent operation even in demanding environments.

| Grade | C | Al | Ti | S | Cu | Fe | Ni |

| Incoloy Pipe | 0.05 max | 0.2 max | 0.6 – 1.2 | 0.03 max | 1.5 – 3.0 | 22.0 min | 38.0 – 46.0 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Incoloy Pipe | 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa – 220 | 30 % |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Incoloy Pipes as per DIN, ISO, JIS or ANSI Standard.

Incoloy Pipe applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

When selecting Incoloy pipes, consider the application’s temperature, corrosive environment, and mechanical stresses. Choose a grade of Incoloy (such as 800 825) that matches your specific requirements for strength, oxidation resistance, and compatibility with the chemicals present. Ensure the pipe dimensions and wall thickness meet your pressure and flow needs, consulting with suppliers or engineers for detailed guidance on material selection.

Yes, Incoloy pipes are recyclable. Incoloy is a family of superalloys composed primarily of nickel, chromium, and iron, which are valuable materials in recycling due to their high alloy content. Recycling these pipes helps conserve resources, reduces waste, and can be economically beneficial due to the high value of nickel and chromium in the scrap metal market.

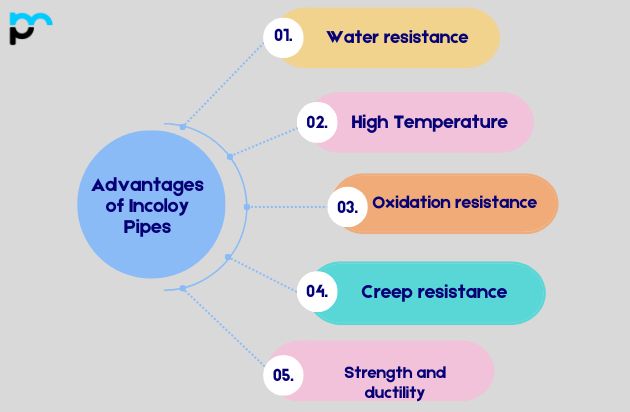

When selecting Incoloy pipes, consider their high resistance to oxidation and corrosion in high-temperature environments, making them ideal for chemical processing, heat treating, and power generation applications. Their excellent mechanical properties at elevated temperatures also ensure reliability and longevity in demanding conditions. Finally, assess the specific alloy composition of Incoloy pipes to match your application’s required strength and performance characteristics.

Incoloy pipes, typically made from nickel-iron-chromium alloys, can withstand a wide range of temperatures depending on their specific composition. They are known for their high-temperature strength and resistance to oxidation and corrosion. Incoloy 800, for example, can handle temperatures up to around 1100°C (2000°F), while Incoloy 825 can withstand temperatures up to approximately 870°C (1600°F). These properties make Incoloy pipes suitable for applications in high-temperature environments such as petrochemical processing, heat treating, and power generation.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.