Home > Copper Nickel > Copper Nickel Bars

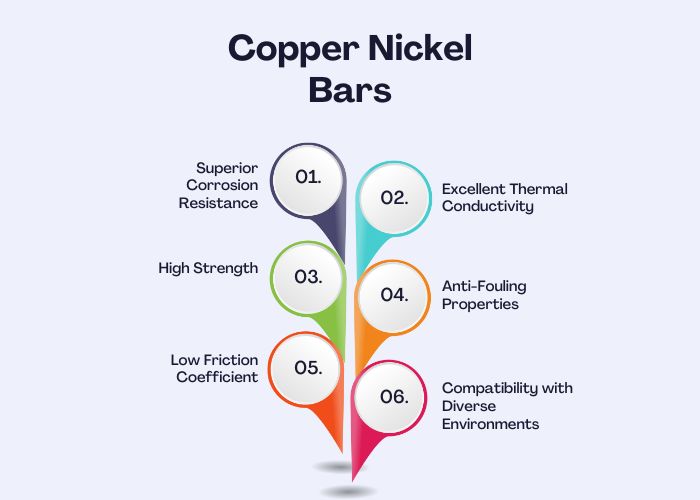

We take pride in offering a wide range of Copper Nickel Bars from top suppliers known for their high-quality products. These bars are essential in various applications of different sizes and grades that meet industry standards. Widely used in construction and engineering, our Copper Nickel Bars are praised for their excellent resistance to corrosion and abrasion, ensuring durability in tough environments. Heat treatment enhances these bars for better mechanical properties across their structure.

| Specifications | ASTM B151, ASME SB151 |

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Range | 5 To 500 mm thick in 100 TO 6000 mm |

| Cu-Ni Round Bars | 6 to 120 mm. |

| Cu-Ni Square Bars | 10 to 200 mm. |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length | 100 to 3660 mm Long |

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

| Grade | Cu | Pb | Fe | Zn | Ni | Mn |

| Copper Nickel | 65.0 min | .05 max | 0.4-1.0 | 1 max | 29-33 | 1 max |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Copper Nickel Bars as per DIN, ISO, JIS or ANSI Standard.

Copper Nickel Bars applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Copper nickel bars can withstand various temperatures, typically from cryogenic lows (-196°C) to elevated highs (300°C). This thermal stability makes them suitable for various applications, including marine environments, where they excel due to their corrosion resistance and mechanical strength across such temperature ranges.

Copper Nickel Bars are resistant to galvanic corrosion due to their inherent ability to form a protective oxide layer that prevents direct contact between dissimilar metals. This property makes them suitable for marine environments and other applications exposed to varying water conditions and metals. Additionally, their balanced composition of copper and nickel enhances their durability and resistance to corrosion over time.

Yes, Copper Nickel bars can be recycled after use. Recycling copper-nickel alloys is feasible and economically viable due to the alloy’s high value of copper and nickel. The process involves melting down the bars and re-extracting the metals, which helps conserve natural resources and reduce environmental impact.

Yes, Copper Nickel Bars are suitable for cryogenic applications due to their excellent low-temperature properties, including good ductility and toughness at extremely low temperatures. They maintain their mechanical strength and corrosion resistance, making them ideal for cryogenic environments such as liquefied natural gas (LNG) storage and transportation systems.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.