Home > Alloy Steel > Alloy Steel Pipes

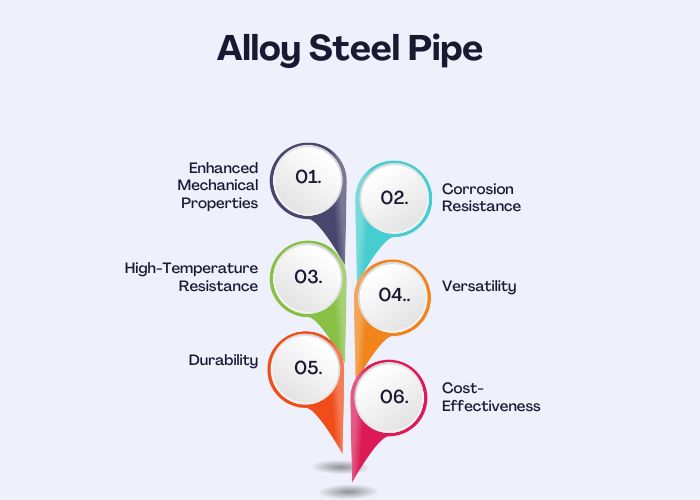

Alloy steel pipes are made from a mix of steel with added elements like chromium, molybdenum, nickel, and the usual iron and carbon. This blend gives them better strength, hardness, and resistance to corrosion and high temperatures compared to regular steel pipes. Found in industries like oil, gas, power generation, and automotive, alloy steel pipes are prized for their durability, reliability, and performance in tough conditions. They serve various purposes, from pipelines to structural parts and machinery, improving the efficiency and dependability of industrial operations.

|

Dimensions |

: |

ASTM, ASME and API |

|

Standard |

: |

ASTM / ASME SA335 |

|

Size |

: |

1/8″NB TO 30″NB IN |

|

Specialized in |

: |

Large Diameter Size |

|

Schedule |

: |

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

|

Form |

: |

Round |

|

Type |

: |

Seamless / Fabricated |

|

Length |

: |

Single Random, Double Random & Cut Length. |

|

End |

: |

Plain End, Beveled End, Threaded |

|

C % |

Mn % |

P % |

S % |

S i% |

Cr % |

Mo % |

|

0.10-0.20 |

0.30-0.60 |

0.025 max |

0.025 max |

0.10-0.30 |

0.50-0.81 |

0.44-0.65 |

|

Tensile Strength, MPa |

Yield Strength, MPa |

Elongation, % |

|

415 min |

205 min |

30 min |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Alloy Steel Pipe as per DIN, ISO, JIS or ANSI Standard.

Alloy Steel Pipe applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Alloy steel pipes are designed to withstand various temperatures, depending on their specific composition and intended use. Typically, they can handle temperatures ranging from -20°C to 650°C (-4°F to 1202°F). This makes them suitable for high-temperature applications, such as power plants and refineries, and low-temperature environments, like cryogenic applications in aerospace or gas processing.

To prevent galvanic corrosion in alloy steel piping systems, use compatible materials for joints and connections (such as alloy steel fittings with alloy steel piping). Where possible, insulate dissimilar metals with non-conductive materials and apply corrosion-resistant coatings or inhibitors. Regular maintenance and monitoring for signs of corrosion are also essential to prevent issues in the long term.

Yes, alloy steel pipes typically require corrosion protection coatings to enhance their durability and prevent degradation over time. These coatings help mitigate the effects of environmental factors such as moisture and chemicals, ensuring the pipes have an extended service life and maintain their structural integrity in various industrial applications.

When selecting alloy steel pipes, consider the required strength and corrosion resistance for the intended application. Evaluate the operating temperature and pressure conditions to ensure the alloy’s compatibility. Additionally, assess factors like weldability, cost-effectiveness, and availability of specific grades needed for your project’s specifications.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.