Home > Alloy Steel > Alloy Steel Pipe Fittings

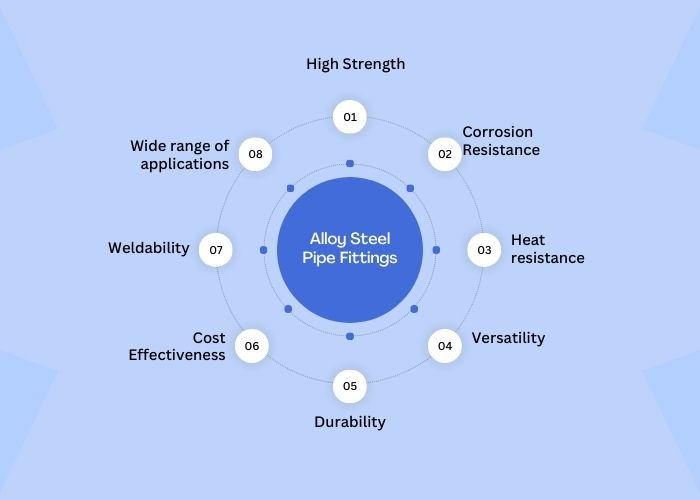

Discover a wide range of top-tier Alloy Steel Pipe Fittings on our product pages, featuring a comprehensive selection of premium solutions. Dive into versatility and reliability with fittings tailored for diverse industrial needs. Our lineup includes precision-engineered fittings that meet stringent durability and corrosion resistance criteria. As a reliable supplier, we prioritize customer satisfaction through customizable options, competitive pricing, and swift delivery. Count on our Alloy Steel Pipe Fittings for exceptional performance across construction, manufacturing, and industrial applications, setting a benchmark for excellence and innovation in every project.

| Material | Size (mm) | SCH/ Class | Thickness | Specification | Manufacturing Method |

|---|---|---|---|---|---|

|

Alloy Steel Pipe Fittings |

15NB to 600NB |

SCH 40 to XXS |

3.91 to 60mm |

A234 WP |

Seamless |

|

200NB to 1800NB |

SCH 10, 20, 30, 40, 80 |

6.35 to 60mm |

A234 WP |

Welded |

| Mechanical Properties of ASTM A234 Alloy Steel Pipe Fittings | ||||

|---|---|---|---|---|

| Grade | Tensile Strength, min. ksi[MPa] | Yield Strength, min. ksi[MPa] | Elongation, min. % | |

| Longitudinal | Transverse | |||

| WP1 | 55-80[380-550] | 30[205] | 20 | 13 |

| WP12 CL1 | 60[415] | 32[220] | 22 | 14 |

| WP12 CL2 | 70[485] | 40[275] | 22 | 14 |

| WP11 CL1 | 60[415] | 30[205] | 22 | 14 |

| WP11 CL2 | 70[485] | 40[275] | 22 | 14 |

| WP11 CL3 | 75[520] | 45[310] | 22 | 14 |

| WP22 CL1 | 60[415] | 30[205] | 22 | 14 |

| WP22 CL3 | 75[520] | 45[310] | 22 | 14 |

| WP24 | 85[585] | 60[415] | 20 | – |

| WP5 CL1 | 60[415] | 30[205] | 22 | 14 |

| WP5 CL3 | 75[520] | 45[310] | 22 | 14 |

| WP9 CL1 | 60[415] | 30[205] | 22 | 14 |

| Chemical Composition of ASTM A234 Alloy Steel Pipe Fittings(%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Grade | C | Mn | P | S | Si | Cr | Mo | Others |

| WP1 | 0.28 | 0.30-0.90 | 0.045 | 0.045 | 0.10-0.50 | – | 0.44-0.65 | – |

| WP12 CL1, WP12 CL2 | 0.05-0.20 | 0.30-0.80 | 0.045 | 0.045 | 0.60 | 0.80-1.25 | 0.44-0.65 | – |

| WP11 CL1 | 0.05-0.15 | 0.30-0.60 | 0.030 | 0.030 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | – |

| WP11 CL2, WP11 CL3 | 0.05-0.20 | 0.30-0.80 | 0.040 | 0.040 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | – |

| WP22 CL1, WP22 CL3 | 0.05-0.15 | 0.30-0.60 | 0.040 | 0.040 | 0.50 | 1.90-2.60 | 0.87-1.13 | – |

| WP24 | 0.05-0.10 | 0.30-0.70 | 0.020 | 0.010 | 0.15-0.45 | 2.20-2.60 | 0.90-1.10 | *A |

| WP5 CL1, WP5 CL3 | 0.15 | 0.30-0.60 | 0.040 | 0.030 | 0.50 | 4.0-6.0 | 0.44-0.65 | – |

| WP9 CL1, WP9 CL3 | 0.15 | 0.30-0.60 | 0.030 | 0.030 | 1.00 | 8.0-10.0 | 0.90-1.10 | – |

| WPR | 0.20 | 0.40-1.06 | 0.045 | 0.050 | – | – | – | *B |

| WP91 | 0.08-0.12 | 0.30-0.60 | 0.020 | 0.010 | 0.20-0.50 | 0.85-1.05 | 0.85-1.05 | *C |

| WP911 | 0.09-0.13 | 0.30-0.60 | 0.020 | 0.010 | 0.10-0.50 | 0.90-1.10 | 0.90-1.10 | *D |

| WP92 | 0.07-0.13 | 0.30-0.60 | 0.020 | 0.010 | 0.50 | 0.30-0.60 | 0.30-0.60 | *E |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Alloy Steel Pipe Fittings as per DIN, ISO, JIS or ANSI Standard.

Alloy Steel Pipe Fittings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Yes, alloy steel pipe fittings are recyclable. Alloy steel is a type of steel containing various alloying elements such as chromium, nickel, and molybdenum. These compounds can be separated and recovered through various recycling processes, such as melting and finishing. Recycling alloy steel pipe fittings helps conserve natural resources, reduce energy consumption, and reduce environmental impact by diverting waste to landfills furthermore, it can use recycled alloy steel for new pipe fittings and other materials, contrib

The most common alloys in alloy pipes are chromium, nickel, molybdenum, vanadium, and manganese. These components are added to improve properties such as strength, corrosion resistance and thermal resistance according to the specific requirements of the application

Proper installation and maintenance of alloy steel pipe fittings is critical for optimum performance and longevity. Follow the manufacturer’s recommendations for installation, including proper assembly, torque, and cover. Routine inspections and maintenance, such as checking for leaks, corrosion, or wear and replacing damaged components when necessary, help ensure pipeline integrity and reliability.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.