Home > Alloy Steel > Alloy Steel Forged Fittings

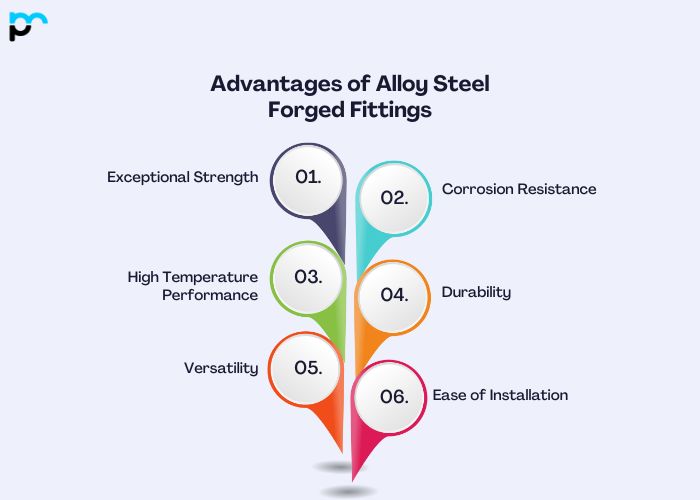

Alloy Steel Forged Fittings are robust components made from alloy steel through a forging process, ensuring enhanced strength and durability. These fittings are commonly used in high-pressure and high-temperature applications, where their superior mechanical properties excel. They offer excellent resistance to corrosion, making them ideal for challenging environments. Alloy Steel Forged Fittings are crucial in industries like oil and gas, chemical processing, and power generation due to their reliability and performance under demanding conditions.

| Specifications | Alloy Steel |

|---|---|

| Size | 1/8” NB TO 48” NB. |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Type | Seamless / Welded / Fabricated |

| Thickness | Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS |

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % |

| Alloy Steel | 415 | 585 | 20 |

| Grade | C | Mn | Si | S | P | Cr | Mo |

| Alloy Steel | 0.08 – 0.12 | 0.3 – 0.6 | 0.5 | 0.01 | 0.02 | 8.5 – 9.5 | 0.85 – 1.05 |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Alloy Steel Forged Fittings as per DIN, ISO, JIS or ANSI Standard.

Alloy Steel Forged Fittings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Alloy Steel Forged Fittings can be susceptible to galvanic corrosion when in contact with dissimilar metals in an electrolyte solution, potentially causing accelerated corrosion. Proper insulation or the use of compatible materials can help mitigate this risk.

Yes, Alloy Steel Forged Fittings can be recycled after use. The alloy steel material retains its properties even after the forging process, allowing for efficient recycling and reuse in various industries, promoting sustainability and resource conservation.

Alloy Steel Forged Fittings are often suitable for cryogenic applications due to their excellent mechanical properties at low temperatures. Their high strength, toughness, and resistance to embrittlement make them a reliable choice for handling extreme cold conditions in aerospace, medical, and energy industries.

Yes, Alloy Steel Forged Fittings can be used for underground applications. Their corrosion resistance and durability make them suitable for withstanding underground conditions, providing reliable performance in buried piping systems for industries like utilities, infrastructure, and construction.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.