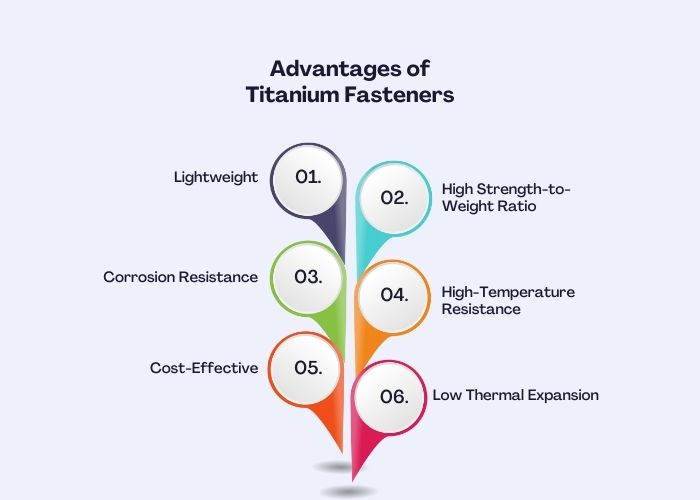

Titanium Fasteners, including bolts, screws, nuts, washers and studs, are made of titanium alloys known for exceptional strength-to-weight ratio and corrosion resistance. This makes titanium a coveted material, especially in harsh environments like marine, chemical, and aerospace builds. The ability to withstand extreme conditions, high temperatures, and stresses underscores why titanium is desired in durable environments, and longevity is paramount.

| Titanium Grade 2 Fasteners Material Specification | Titanium Bolts, UNS R50400 Bolts |

|---|---|

| Standard | DIN, UNI, ISO, JIS, GB, IS, BS, ASME, ANSI, ASTM and all International Standards |

| Titanium Grade 2 Fasteners/ Bolts Size | M2, M2.5, M3, M4, M5, M6, M8, M10, M12, M14, M16, M20, M24, M30, M36 to M160 |

| Length | 3 mm to 200 mm |

| Titanium Grade 2 Bolts, Studs Threads: | METRIC, BSW, BSF, UNC, UNF or as required |

| Titanium Grade 2 Fasteners Standard: | ANSI – American National Standards Institute

|

| Source of raw materials | Tata Steel, JSPL, RINL, Usha Martin, Dhamm Steel, Mukund Steel etc. |

| SCOPE OF MANUFACTURE |

|

| Titanium Grade 2 Fasteners In Form of: | Hex, Square, Round, Threading as per Gauge Etc. |

| Head drive: | Phillips, Slotted, Phillips/Slot, Six-Lobe, etc |

| Titanium Grade 2 bolting Test Certificate: | Manufacturer Test Certificate as per EN 10204 / 3.1 |

| Titanium Grade 2 Fasteners finishing: | Zinc (yellow, white, blue, black), black oxide, Geometry, Dacroment, anodizing, nickel plated, plated zinc-nickel, Titanium Grade 2 : Passivated Self-Colour, Hot Dip Galvanised (HDG), Bright Zinc Plated (BZP), Sherardized, Titanium Grade 2 , Mechanically Applied coating and some special one like DACROMET |

| Production process | M2-M24: Cold Froging, hot forging M24-M100, machining and CNC for Customized connecting element |

| Titanium Grade 2 bolting materials Surface Coating: |

|

| Popular Types of Titanium Grade 2 Bolts | Hex Bolts, Flange Bolts, Hex Head Bolts, Lag Bolts, Square Bolts, Eye Bolts, U Bolts, T Bolts, Counter sunk Bolts etc. |

| Popular Types of Titanium Grade 2 Nut | Eye, Dome, Hex Head Nut, Panel, Lock, Coupling, Square, Acorn, T, Wing etc. |

| Popular Types of Titanium Grade 2 Screw | Socket Set Fasteners, Anchor Fasteners, Blind Rivet, Threaded Fasteners, Socket Head Fasteners, Machine Fasteners, Concrete Fasteners, Shoulder Fasteners, Panel Fasteners, Hex Head Cap Fasteners etc. |

| Popular Types of Titanium Grade 2 Washer | Machine Washers, Star Washers, Flat Washer, Lock Washer, Split Washer, Sealing Washer etc. |

| Titanium Grade 2 Fasteners Packing: | IN BULK: canton, pallet, Small Boxs / carton / pallet, or customer request |

| Grade | C | N | O | H | Ti | Fe |

| Titanium Gr 2 | 0.10 max | 0.03 max | 0.25 max | 0.015 max | bal | 0.30 max |

| Titanium Gr 5 | 0.10 max | 0.05 max | 0.20 max | 0.015 max | bal | 0.40 max |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Gr.2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20 % |

| Gr.5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14 % |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Titanium Fasteners as per DIN, ISO, JIS or ANSI Standard.

Due to their remarkable properties, titanium fasteners find extensive industrial use across various sectors. Their high strength, lightweight nature, and exceptional corrosion resistance make them indispensable in the aerospace, automotive, marine, medical, and chemical processing industries.

Yes, titanium fasteners can be welded, but the process requires expertise due to titanium’s reactivity and temperature. Welding titanium fasteners typically use special processes such as TIG (Tungsten Inert Gas) in a controlled environment to prevent contamination and ensure a strong weld joint. For proper grooming, clean materials and precise temperature control are needed to successfully weld titanium fasteners.

Titanium fasteners are ideal for hygienic and sanitary applications due to their corrosion resistance, biocompatibility, and non-reactivity. These qualities ensure they meet the stringent requirements of environments where cleanliness and sanitation are paramount.

Yes, titanium fasteners are highly recyclable after use. Due to titanium’s durability and ability to retain its properties through recycling processes, it can be melted down and reused without significant loss of quality. Recycling titanium fasteners helps to conserve resources and reduce environmental impact, making it an eco-friendly choice for sustainable practices.

Yes, titanium fasteners are well-suited for cryogenic applications due to their excellent low-temperature properties. Titanium maintains its strength, toughness, and corrosion resistance at cryogenic temperatures, making it a reliable choice for extreme cold environments. Its ability to withstand such conditions without becoming brittle ensures the integrity of connections in cryogenic systems.

|

Titanium Grade 2 Fasteners Type |

SIZE |

GRADE |

ASME |

ISO |

ASTM |

|---|---|---|---|---|---|

|

Titanium Grade 2 Socket Head Cap Fasteners |

M1.6 to M64 |

12.9 |

B18.3.1 M |

4762 |

A574M |

|

Titanium Grade 2 Socket Low Head Cap Fasteners |

M4 to M20 |

10.9 |

|||

|

Titanium Grade 2 Socket Head Shoulder Fasteners |

M6 to M24 |

012.9 |

B18.3.3M |

||

|

Titanium Grade 2 Countersunk Socket Head Fasteners |

M3 to M20 |

012.9 |

B18.3.5M |

10642 |

F835M |

|

Titanium Grade 2 Button Head Socket Fasteners |

M3 to M12 |

012.9 |

B18.3.4M |

7380 |

F835M |

|

Titanium Grade 2 Flange Button Head Socket Fasteners |

M3 to M10 |

012.9 |

F835M |

||

|

Titanium Grade 2 Knurled Point Socket Set Fasteners |

M3 to M20 |

45H |

B18.3.6M |

4029 |

F912M |

|

Titanium Grade 2 Flat Point Socket Set Fasteners |

M6 to M12 |

45H |

B18.3.6M |

4026 |

F912M |

|

Titanium Grade 2 Dog Point Socket Set Fasteners |

M3 to M20 |

45H |

B18.3.6M |

4028 |

F912M |

|

Titanium Grade 2 Cone Point Socket Set Fasteners |

M3 to M12 |

45H |

B18.3.6M |

4027 |

F912M |

|

Titanium Grade 2 Plain Point Socket Set Fasteners |

M3 to M20 |

45H |

B18.3.6M |

4029 |

F912M |

|

Titanium Grade 2 Taper Pressure Plug |

M8 to M22 |

– |

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.