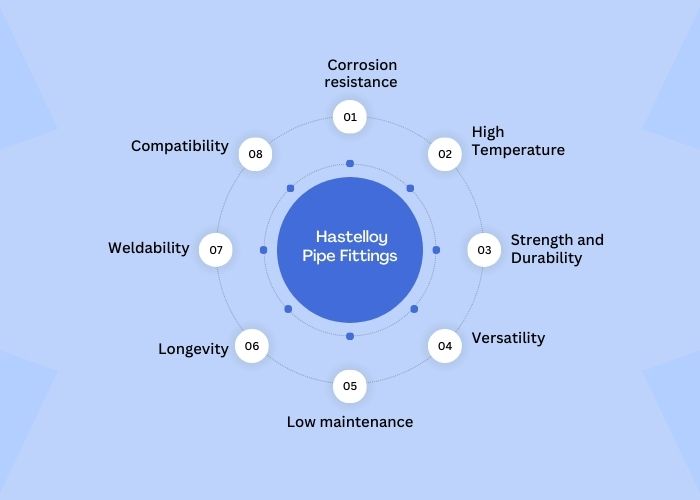

Hastelloy pipe fittings are components that connect and control the flow of Hastelloy pipe in a variety of industrial applications. Hastelloy is a high-performance alloy known for exceptional corrosion resistance in harsh environments, making it ideal for industries like chemical processing, oil and gas, aerospace, etc. These fittings are designed to ensure leak-free connections, withstand high temperatures and pressures, and maintain integrity in corrosive conditions, offering reliability and longevity in critical piping systems.

| Specification | Hastelloy |

| Grade | Hastelloy |

| Type | Seamless / Welded / Fabricated |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Range | ½”NB to 24”NB in Sch 10s, 40s, 80s, 160s, XXS. |

| Dimensions | ANSI/ASME B16.9, B16.28, MSS-SP-43. |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy Pipe Fittings | 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000 , MPa – 690 | Psi – 45000 , MPa – 310 | 45 % |

| C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P | |

| Hastelloy Pipe Fittings | 0.010 max | 0.50 max | 0.08 max | 0.02 max | 2.50 max | 50.015 min* | 20.00 – 22.50 | 2.00 – 6.00 | 12.50 – 14.50 | 0.02 max |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Hastelloy Pipe Fittings as per DIN, ISO, JIS or ANSI Standard.

Hastelloy Pipe Fittings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

To select the right Hastelloy Pipe Fittings for your application, start by assessing the specific operating conditions, such as temperature, pressure, and the nature of the conveyed substances. Consider the compatibility of the fittings with your existing piping system, ensuring proper sizing, end connections, and material grade. Consult with experienced engineers or specialists to guide you in choosing fittings that offer the best combination of corrosion resistance, durability, and performance tailored to your application’s requirements.

When installing Hastelloy Pipe Fittings, paying attention to proper alignment and fit is crucial to prevent leaks and ensure system integrity. Consider the recommended installation torque for fittings to avoid over-tightening, which can lead to damage. Verify that all connections are clean and free of contaminants to maintain the corrosion-resistant properties of the fittings over time. Lastly, follow manufacturer guidelines and industry best practices for installation procedures to optimize the performance and longevity of the fittings in your system.

Hastelloy Pipe Fittings are primarily designed for corrosive environments where chemical resistance and high temperatures are critical. While they excel in chemical processing, oil and gas, and aerospace industries, they are not typically used in structural applications that require load-bearing capabilities. For structural purposes, materials specifically engineered for strength and structural integrity are more suitable to ensure safety and compliance with structural requirements.

Hastelloy Pipe Fittings generally do not require corrosion protection coatings due to their inherent corrosion resistance properties. However, specific coatings may be considered for added protection in extremely harsh or specialised environments, though consulting with experts is recommended for tailored advice.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.