Home > Nickel Alloy > Nickel Alloy Pipes

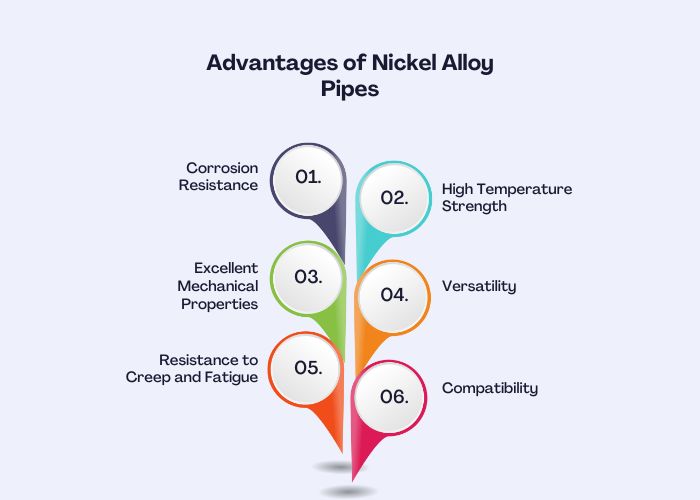

Nickel alloy pipes are made from nickel-based materials known for their strong resistance to corrosion, high temperatures, and mechanical stress. They are widely used in industries like chemical processing, petrochemicals, and aerospace, where tough conditions are common. These pipes come in different grades for specific uses and perform better than traditional materials. Their durability, ability to be welded and capacity to withstand extreme conditions make them essential in important infrastructure and industrial processes.

| Dimensions | : | ASTM, ASME and API |

|---|---|---|

| Standard | : | ASTM A161, ASME SB161 |

| Size | : | 4 to 219mm W. T.: 0.5 to 20mm |

| Specialized In | : | Large Diameter Size |

| Grade | : | Nickel Alloy 200 (UNS No. N02200) |

| Schedule | : | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Form | : | Round, Hydraulic Etc |

| Type | : | Seamless / Fabricated |

| Length | : | Single Random, Double Random & Cut Length. |

| End | : | Plain End, Beveled End, Threaded |

| Cu | Ni | Fe | Mn | C | S | Si |

| 0.25 max | 99.0 min | 0.4 max | 0.35 max | 0.15 max | 0.01 max | 0.1 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.89 g/cm3 | 1370 °C (2550 °F) | Psi – 1,15,000 , MPa –790 | Psi – 52,000 , MPa – 355 | 40 % |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Nickel Alloy Pipes as per DIN, ISO, JIS or ANSI Standard.

Nickel Alloy Pipes applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

To prevent galvanic corrosion in nickel alloy piping systems, use compatible materials to avoid potential differences, apply coatings or isolators between dissimilar metals, and ensure proper cathodic protection. Regular maintenance and monitoring can also help mitigate risks.

Yes, Nickel Alloy pipes can be welded. They require specific welding techniques and filler materials to prevent cracking and corrosion. Proper preparation, control of heat input, and post-weld treatments are essential for ensuring strong, reliable welds.

To maintain nickel alloy pipes, regularly inspect them for signs of corrosion, pitting, or cracking. Clean the pipes using appropriate non-abrasive cleaners to prevent surface damage. Ensure proper storage conditions to avoid exposure to harsh environments, and follow manufacturer guidelines for maintenance and repair procedures.

Nickel alloy pipes generally do not require additional corrosion protection coatings due to their inherent resistance to corrosion in various environments. However, in extremely aggressive conditions or specific applications, protective coatings might be applied to extend their lifespan. Always consult material specifications and application requirements to determine the need for coatings.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.