Titanium flanges connect pipes, valves, and other parts in piping systems. They’re made from titanium, which is lightweight, resistant to corrosion, and known for its strong yet light properties. These flanges are reliable and widely used in different industries.

| Product Name | Titanium Flanges |

|---|---|

| Size Range | 1/2″ (15 NB) to 48″ (1200NB) |

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standards / Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, BS, GOST, MSS SP-44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605 |

| Flange Face Types / Connection Type | Flat Face Flange (FF), Raised Face Flange (RF), Ring Joint Flange (RTJ), Lap Joint Flange, Male and Female Flange (M&F), Large and Small Tongue-and-Groove Flange (T&G) |

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, ASA, API-605, MSS SP44, AWWA, Custom Drawings |

| Custom Design | As per your drawing | AS, BS, ANSI, DIN, JIS | Equal and Reducing Configurations |

| Material Test Certificates (MTC) | As per EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103 |

| Test Certificates | 100% Radiography Test Report, EN 10204/3.1B, Raw Materials Certificate, Third Party Inspection Report, etc |

| Tests | Hydrostatic testing machine, Direct-reading Spectrograph, UI trasonic flaw detector, X-ray detector, Magnetic particle detector |

| Equipment / Machines | Press machine, Pushing Machine, Bending machine, Sand-blasting machine, electric bevelling machine, etc. |

| Coating | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| Origin | Indian / USA / Japan / West Europe / Korean |

| Applications/Usage | Offshore, Oil Field, Shipbuilding, Water System, Natural Gas, Pipe Projects, Electric Power, etc. |

| Top Export Network | USA, UK, Qatar, Mexico, Nigeria, Saudi Arabia, Kuwait, Iran, Kazakhstan, Bahrain, Vietnam, Indonesia, Norway, Ghana, Colombia, Azerbaijan, Libya. |

| Grade | C | N | O | H | Ti | Fe |

| Titanium Grade 1 | .08 Max | .03 Max | .18 Max | .015 Max | Bal | .20 Max |

| Titanium Grade 4 | .08 Max | .05 Max | .40 Max | .015 Max | Bal | .50 Max |

| Titanium Grade 7 | .08 Max | .03 Max | .25 Max | .015 Max | Bal | .30 Max |

| Titanium Grade 9 | .08 Max | .03 Max | .15 Max | .015 Max | – | .25 Max |

| Titanium Grade 12 | .08 Max | .03 Max | .25 Max | 0.15 Max | – | .30 Max |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 4.5 G/Cm3 | 1665 °C (3030 °F) | Psi – 39900, MPa – 275 | Psi – 49900, MPa – 344 | 20 % |

| 4.43 G/Cm3 | 1632 °C (2970 °F) | Psi – 128000, MPa – 880 | Psi – 138000, MPa – 950 | 14 % |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Titanium Flanges as per DIN, ISO, JIS or ANSI Standard.

Titanium flanges are essential in various industries, from aerospace to chemical processing, marine, and oil and gas. Renowned for their corrosion resistance, lightweight nature, and high strength, they ensure reliability in critical applications. Additionally, their biocompatibility makes them valuable assets in medical and food processing industries. Across sectors, titanium flanges are pivotal in maintaining system integrity and efficiency.

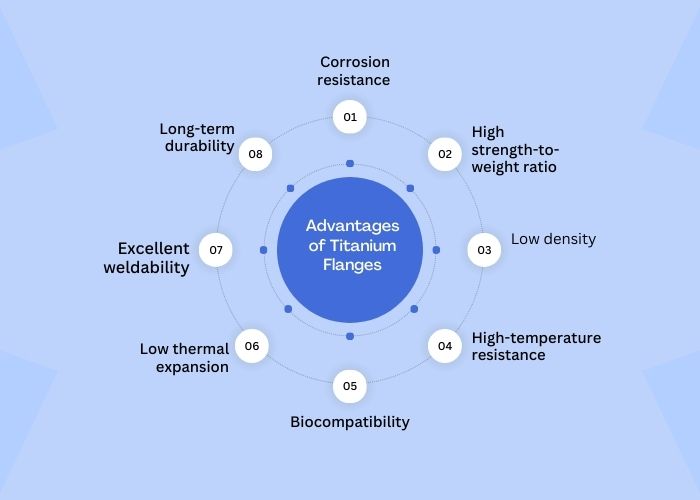

When considering titanium flanges, key factors include their exceptional corrosion resistance, high strength-to-weight ratio, and excellent performance in high-temperature environments. Titanium’s biocompatibility, low thermal expansion, and long-term durability make it ideal for critical applications where reliability and performance under challenging conditions are paramount.

Titanium flanges are highly suitable for high-temperature applications due to their excellent heat resistance and high strength-to-weight ratio. They can withstand elevated temperatures without losing their mechanical properties, making them ideal for environments where heat resistance and durability are crucial. Additionally, Titanium’s corrosion resistance ensures longevity and reliability in diverse industrial settings.

Titanium flanges are highly corrosion-resistant due to their natural oxide layer, which forms spontaneously upon exposure to air or water. This oxide layer provides excellent protection against corrosion in various environments, often eliminating the need for additional coatings. However, specific applications involving extremely aggressive conditions may benefit from additional protective coatings to enhance longevity and performance.

Titanium flanges are suitable for structural applications due to their excellent strength-to-weight ratio, corrosion resistance, and high durability. They are often used in aerospace, marine, and industrial settings, where these properties are critical for ensuring long-term structural integrity and performance.

| NOMINAL SIZE | DIMENSIONS | WEIGHT (KG) | ||||

|---|---|---|---|---|---|---|

| NPS (Inches) | DN (mm) | FLANGE MM | FLANGE THICKNESS | SOW SW | WN | BLIND |

| 1/2 | 15 | 88.9 | 11.2 | 0.4 | 0.5 | 0.4 |

| 3/4 | 20 | 98.6 | 12.7 | 0.6 | 0.7 | 0.6 |

| 1 | 25 | 108 | 14.2 | 0.8 | 1 | 0.9 |

| 1 1/4 | 32 | 117.3 | 15.7 | 1 | 1.3 | 1.2 |

| 1 1/2 | 40 | 127 | 17.5 | 1.3 | 1.7 | 1.5 |

| 2 | 50 | 152.4 | 19.1 | 2.1 | 2.6 | 2.4 |

| 2 1/2 | 65 | 177.8 | 22.4 | 3.3 | 4.1 | 3.9 |

| 3 | 80 | 190.5 | 23.9 | 3.9 | 4.9 | 4.9 |

| 3 1/2 | 90 | 215.9 | 23.9 | 4.8 | 6.1 | 6.2 |

| 4 | 100 | 228.6 | 23.9 | 5.3 | 6.8 | 7.0 |

| 5 | 125 | 254 | 23.9 | 6.1 | 8.6 | 8.6 |

| 6 | 150 | 279.4 | 25.4 | 7.5 | 10.6 | 11.3 |

| 8 | 200 | 342.9 | 28.4 | 12.1 | 17.6 | 19.6 |

| 10 | 250 | 406.4 | 30.2 | 16.5 | 24 | 28.6 |

| 12 | 300 | 482.6 | 31.8 | 26.2 | 36.5 | 43.2 |

| 14 | 350 | 533.4 | 35.1 | 34.6 | 48.4 | 58.1 |

| 16 | 400 | 596.9 | 36.6 | 44.8 | 60.6 | 76.1 |

| 18 | 450 | 635 | 39.6 | 48.9 | 68.3 | 93.7 |

| 20 | 500 | 698.5 | 42.9 | 61.9 | 84.5 | 122.0 |

| 24 | 600 | 812.8 | 47.8 | 86.9 | 115 | 185.0 |

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.