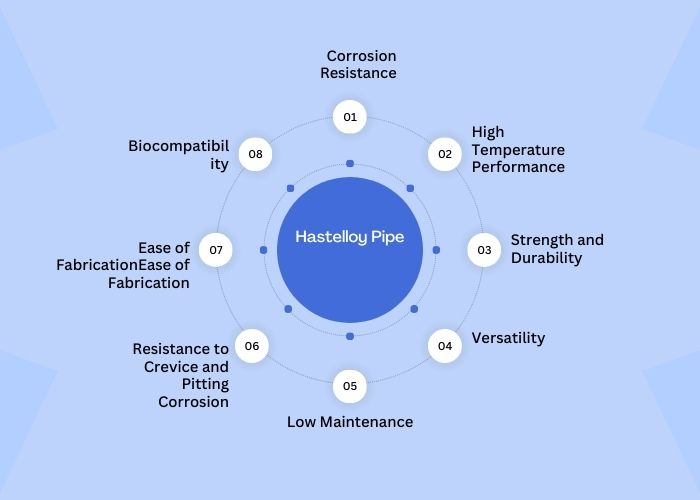

Hastelloy pipes are made from nickel-based alloys known as Hastelloy, prized for their strong resistance to corrosion, oxidation, and high temperatures. Due to their strength, durability, and reliability, they are widely used in demanding fields such as chemical processing, aerospace, marine engineering, and nuclear industries. These qualities make them perfect for critical applications in tough conditions.

|

Dimensions |

: |

ASTM, ASME and API |

|

Standard |

: |

ASTM B622, B619, B626 / ASME SB622, SB619, SB626 |

|

Size |

: |

15NB TO 150 NB IN |

|

Specialized in |

: |

Large Diameter Size |

|

Grade |

: |

Hastelloy C276 (UNS No. N10276), Hastelloy C22 (UNS No. N06022), Hastelloy B2 (UNS No. N10665), Hastelloy C-4 (UNS No. N06455) |

|

Schedule |

: |

SCH20, SCH30, SCh40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

|

Form |

: |

Round, Hydraulic Etc |

|

Type |

: |

Seamless / ERW / Welded / Fabricated / LSAW Pipes |

|

Length |

: |

Single Random, Double Random & Cut Length. |

|

End |

: |

Plain End, Beveled End, Threaded |

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| Hastelloy Pipe | 0.010 max | 1.00 max | 0.08 max | 0.03 max | 2.50 max | 50.99 min* | 14.50 – 16.50 | 4.00 – 7.00 | 15.00 – 17.00 | 0.04 max |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy Pipe | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Hastelloy Pipe as per DIN, ISO, JIS or ANSI Standard.

Hastelloy Pipe applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Hastelloy pipes are renowned for their exceptional resistance to high temperatures and corrosion. Depending on the specific alloy grade (e.g., Hastelloy C276, Hastelloy C22), these pipes can withstand temperatures ranging from cryogenic to around 1200°C (2200°F). This makes them suitable for various industrial applications with prevalent extreme temperatures and corrosive environments.

Maintaining Hastelloy pipes involves regular inspection for signs of corrosion or damage, periodic cleaning using mild detergents or solvents, avoiding abrasive materials, preventing contact with dissimilar metals to prevent galvanic corrosion, considering protective coatings for harsh environments, monitoring operating conditions, promptly addressing any issues, and considering professional maintenance for critical applications.

Yes, Hastelloy pipes are recyclable. Hastelloy is a family of corrosion-resistant alloys primarily composed of nickel, chromium, and molybdenum, among other elements. These alloys can be recycled and reused to reclaim valuable metals, making them environmentally sustainable choices for various industrial applications where corrosion resistance is crucial. Recycling Hastelloy pipes helps conserve resources and reduces the environmental impact associated with metal production.

Yes, Hastelloy pipes are suitable for cryogenic applications due to their excellent mechanical properties at low temperatures, including high strength and resistance to brittleness. They offer good thermal stability and corrosion resistance in extremely cold environments, making them a reliable choice for cryogenic piping systems.

Call Us: +91 7208967217

Email: sales@www.pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.