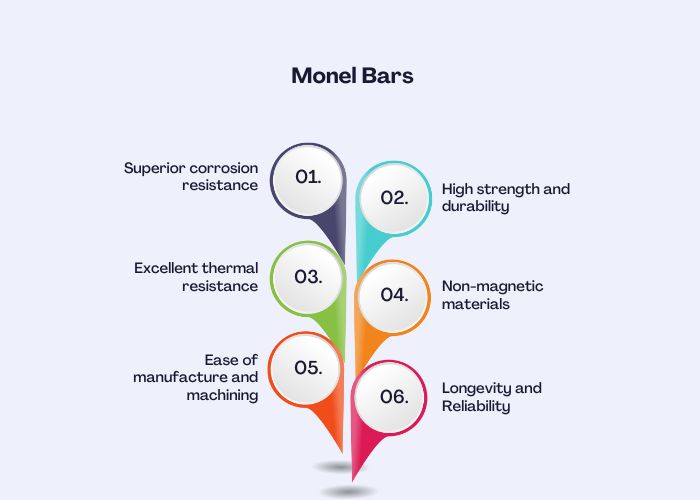

Explore our selection of Monel Bars, showcased on our product pages, offering premium-grade solutions tailored to diverse industrial needs. Our bars are meticulously designed for durability and corrosion resistance, ensuring they meet rigorous standards. As a trusted supplier, we prioritize customer satisfaction with customizable options, competitive pricing, and prompt delivery. Whether for aerospace, chemical processing, or marine applications, our Monel bars exceed industry benchmarks, providing dependable solutions backed by consistent quality and performance commitment.

| Specifications | : | ASTM B164 / ASTM SB164 |

| Dimensions | : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Size | : | 5 mm To 500 mm |

| Diameter | : | 0.1 mm to 100 mm |

| Length | : | 100 mm To 3000 mm Long & Above |

| Finish | : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Tolerance | : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Form | : | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Alloy state | Tensile strength Rm N/mm² | Yield strength R P0. 2 N/mm² | Elongation A 5 % |

| Monel | 480 | 170 | 35 |

| Alloy | % | Ni | Cu | Fe | C | Mn | Si | S |

| Monel | Min. | 63 | 28 | |||||

| Max. | 34 | 2.5 | 0.3 | 2 | 0.5 | 0.024 |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Monel Bars as per DIN, ISO, JIS or ANSI Standard.

Monel Bars applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

When installing Monel bars, consider their superior corrosion resistance and high strength. Ensure proper support and anchoring to accommodate their weight and structural integrity. Using compatible fasteners and fittings is crucial to maintain the material’s integrity and longevity in diverse environmental conditions. Professional installation with attention to material-specific handling guidelines is recommended for optimal performance.

Yes, Monel Bars can be used effectively in structural applications where corrosion resistance and strength are crucial. Their superior corrosion resistance suits them for marine environments and chemical processing plants. Monel Bars also offer high strength, durability, and excellent thermal properties, making them ideal for structural components that require reliability and longevity in harsh conditions.

Monel bars generally do not require corrosion protection coatings due to their inherent resistance to corrosion in various environments, including seawater and acidic conditions. This resistance is primarily due to their high nickel and copper content. However, in specific applications where prolonged exposure to harsh conditions is expected, additional protective coatings may be applied for added durability and longevity.

Yes, Monel bars are recyclable. Monel is primarily composed of nickel and copper, valuable and recyclable metals. Recycling Monel bars involves melting the material to separate and reuse the nickel and copper components, reducing the need for new raw materials and minimizing environmental impact. This process helps maintain sustainability while benefiting from Monel’s durable and corrosion-resistant properties in various applications.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.