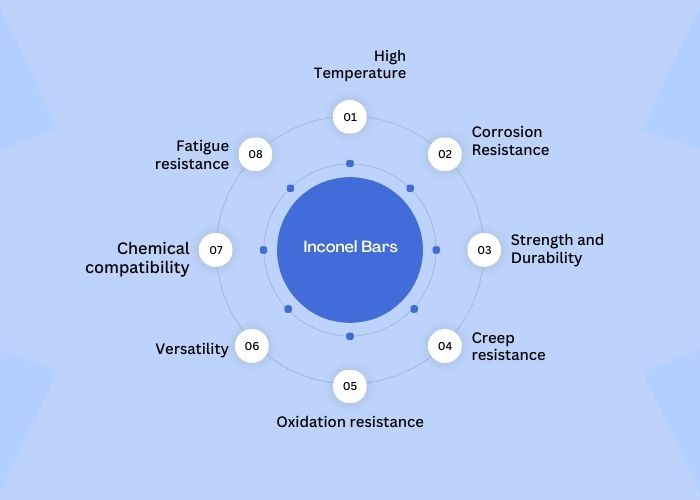

Discover our comprehensive selection of Inconel bars on our product pages, showcasing high-quality solutions tailored to diverse industrial needs. These bars are precision-engineered for exceptional durability and corrosion resistance, meeting stringent standards. As a trusted supplier, we prioritize customer satisfaction with customizable options, competitive pricing, and timely delivery. Whether for aerospace, chemical processing, or marine applications, our Inconel bars exceed industry expectations. Enhance your projects with our reliable and innovative solutions, backed by our commitment to quality and performance.

| Standard | ASTM B166, B446, B425/ASME SB166, SB446, SB425 |

|---|---|

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Round bar Size | Diameter: 3-~800mm |

| Hex Bar Size | 2-100mm A/F |

| Square Bar Size | 4 to 100mm |

| Angle Bar Size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Rectangular Size | 33 x 30mm to 295 x 1066mm |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Condition | Hardened & tempered, annealed |

| Technique | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Processing | Bar cutting to 650mm |

| Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 135,000 , MPa – 930 | Psi – 70,000 , MPa – 482 | 45 % |

| Inconel 600 | 72.0 min | 14.0 – 17.0 | 6.0 – 10.0 | 0.15 max | 1.0 max | 0.015 max | 0.5 max | 0.5 max | 0.5 max |

| Grade | Ni | Cr | Cu | C | Mn | S | Mo | Si | Co |

| Inconel 718 | 50 – 55 | 17 – 21 | 0.3 max | 0.08 max | 0.35 max | 0.015 max | 2.8 – 3.3 | 0.35 max | 1.0 max |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UK, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UK, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Inconel Bars as per DIN, ISO, JIS or ANSI Standard.

Inconel Bars applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Yes, Inconel bars can be welded using conventional welding techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW). However, due to its high nickel content and specific composition, welding Inconel requires careful preparation and use of compatible filler metals to ensure proper weld integrity and resistance to corrosion and heat.

Inconel bars are highly corrosion-resistant in various environments, including acidic and marine conditions. They exhibit excellent oxidation resistance and can withstand high temperatures, making them suitable for challenging applications with critical corrosion resistance. However, their resistance can vary depending on the specific alloy composition and environmental factors, so proper material selection based on the application is important for optimal performance and longevity.

Inconel Bars are generally not recommended for hygienic and sanitary applications where direct contact with food or pharmaceuticals is required. This is because Inconel offers exceptional high-temperature and corrosion resistance and is not inherently food-safe or easily cleanable to meet strict sanitary standards. Materials like stainless steel or certain plastics are more commonly used in such applications due to their smooth surfaces, ease of cleaning, and regulatory compliance for hygiene.

Inconel Bars are generally resistant to galvanic corrosion when paired with compatible metals in similar environments. However, galvanic corrosion can occur when coupled with dissimilar metals due to their different electrochemical potentials. Proper material selection and insulation methods can mitigate this risk, ensuring optimal performance in diverse applications.

Call Us: +91 7208967217

Email: sales@pipingmart.co.uk

PipingMart.co.uk: Your premier B2B metal piping portal in Midland, UK. Explore our extensive range of high-quality pipes, fittings, flanges, and more from worldwide suppliers at competitive prices. Trusted by industry professionals, we offer reliable sourcing and exceptional service.

©2024 Piping Mart. All Rights Reserved.